Liner Technology Guide: Types, Applications, Benefits

Introduction

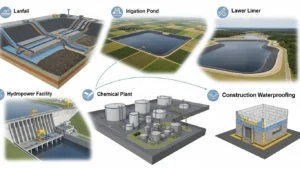

Across industries such as environmental protection, energy infrastructure, construction, and manufacturing, advanced containment systems play a vital role in safety, efficiency, and sustainability. Moreover, liner technology has emerged as a critical solution for controlling fluid migration, preventing contamination, and extending the lifespan of infrastructure. From landfill containment to hydropower reservoirs and geothermal wells, engineered liners support both regulatory compliance and long-term operational reliability.

This guide examines how liner systems function, the various types available, the materials used, and their applications across different industries. Additionally, it examines benefits, limitations, standards, and future trends to help readers understand why liners are indispensable in modern engineering.

What Is a Liner System?

A liner system is an engineered barrier that restricts the movement of liquids, gases, or contaminants between two environments. Specifically, liner technology refers to the science and engineering behind these barriers, including material selection, structural design, and installation methods. Liners may be flexible or rigid, single or multilayered, and designed to withstand chemical exposure, mechanical stress, or extreme temperatures. Furthermore, they ensure operational safety and environmental protection across multiple industries.

Types of Liner Systems

Geomembrane Liners

Geomembrane liners consist of impermeable synthetic polymer sheets. They are widely used in landfills, wastewater facilities, reservoirs, canals, and mining operations. Additionally, geomembranes offer long-term durability and chemical resistance, making them essential for environmental containment.

Common variants include:

-

High-density polyethylene liners for chemical resistance

-

Linear low-density polyethylene liners for flexibility

-

Polyvinyl chloride liners for ease of installation

-

Ethylene propylene diene monomer liners for elasticity and weather resistance

These liners form the backbone of modern containment solutions.

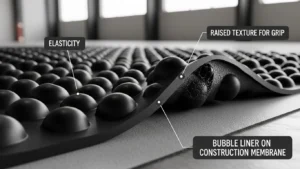

Bubble Liner Systems

Bubble liner systems provide a textured surface that improves safety and processing efficiency. They are commonly used in waterproofing membranes and construction materials. In particular, the Bubble Liner solution developed by Loparex enhances grip, reduces slippage, and improves film elasticity, showcasing the evolution of liner technology beyond basic containment.

Liner-Based Stimulation Systems

In the oil and gas sector, operators use liner-based stimulation systems to enhance reservoir productivity without hydraulic fracturing. These systems deploy high-strength liner assemblies equipped with mechanical or jetting mechanisms. As a result, they reduce fluid use and lower environmental risks while maintaining production efficiency.

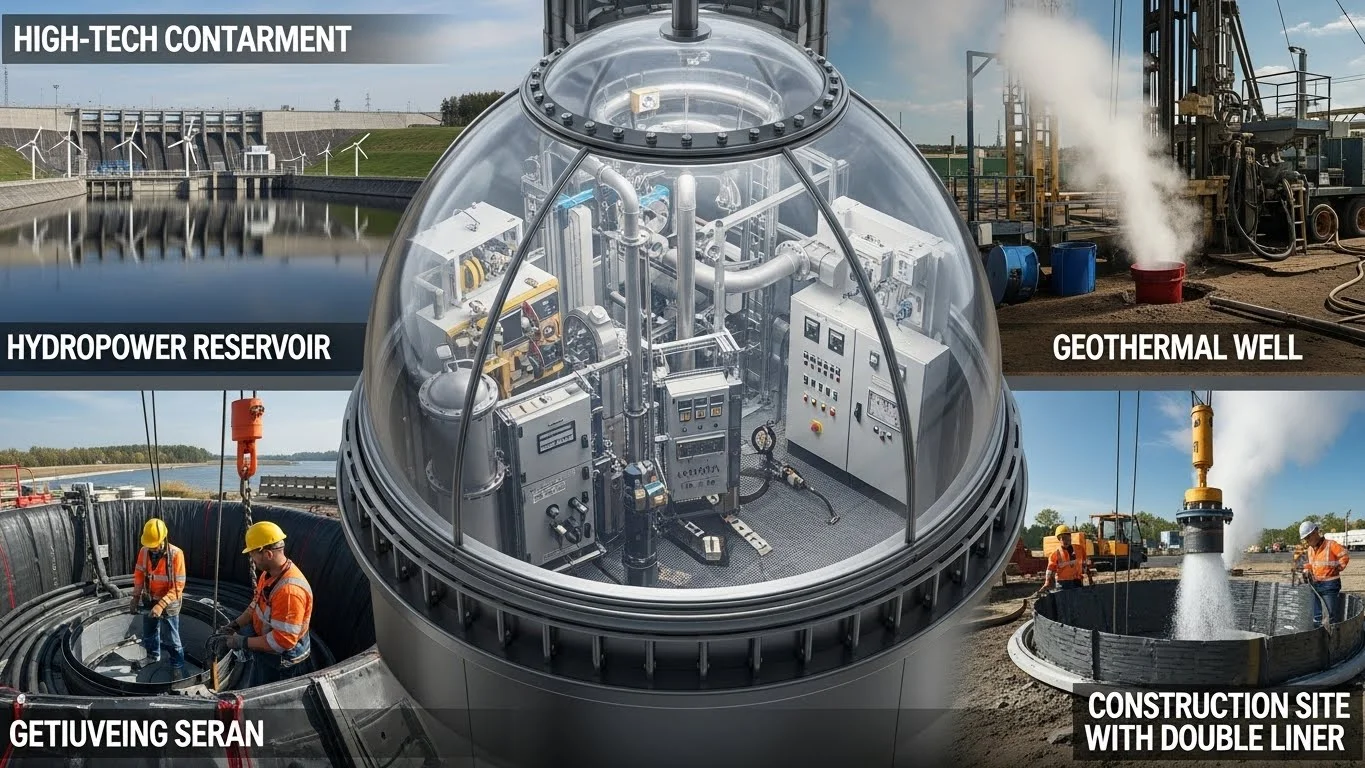

Corrosion-Resistant Liners for Energy Applications

In geothermal and high-temperature environments, corrosion poses a major challenge. Specialized liner systems made from reinforced polymers or composites provide an effective barrier against corrosive fluids. For example, advanced liners extend well life and reduce reliance on expensive corrosion-resistant alloys, improving both efficiency and safety.

Double and Composite Liners

Double liner systems utilize two impermeable layers separated by a detection zone, enabling early leak detection. Additionally, composite liners combine geomembranes with clay or geotextiles to improve performance in complex environments.

How Liner Systems Work

Liner systems function by creating a continuous, low-permeability barrier that isolates fluids from surrounding soil, rock, or structures. Moreover, effectiveness depends on several factors, including material permeability, seam integrity, subgrade stability, and proper anchoring.

Installation techniques include thermal welding, extrusion welding, and mechanical fastening. In addition, teams implement quality assurance measures such as vacuum testing and electrical leak detection to ensure long-term performance.

Key Applications Across Industries

Environmental Protection and Waste Management

Landfills rely on engineered liners to prevent leachate from contaminating groundwater. Wastewater treatment plants use similar systems to contain sludge and process water safely. Importantly, these systems reduce environmental risks and maintain regulatory compliance.

Water Storage and Management

Reservoirs, ponds, irrigation canals, and stormwater basins depend on impermeable liners to minimize seepage and maintain water quality. Consequently, these liners play a critical role in resource conservation.

Energy Infrastructure

Pumped storage hydropower facilities use synthetic liners to improve efficiency and reduce excavation costs. Research published by the U.S. Department of Energy shows how novel liner solutions enhance reservoir performance while lowering lifecycle costs.

Similarly, geothermal wells and oilfield operations depend on advanced containment systems for corrosion control and reservoir stimulation.

Industrial and Mining Operations

Mining sites use liners in heap leach pads and tailings ponds to contain hazardous fluids. Additionally, chemical plants rely on secondary containment liners to prevent spills and ensure operational safety.

Construction and Waterproofing

Modern building envelopes, tunnels, and basements incorporate liner systems to protect against moisture ingress and structural degradation. Furthermore, bubble liners improve safety and ease of installation in construction materials.

Features and Benefits

The adoption of linear technology is driven by several advantages:

-

High chemical and UV resistance

-

Long service life with minimal maintenance

-

Reduced environmental risk

-

Compliance with environmental regulations

-

Adaptability across industries

-

Improved safety during installation and operation

Notably, these benefits make liner systems cost-effective compared to traditional barriers like concrete or steel.

Challenges and Limitations

Despite their benefits, liners face certain challenges:

-

Improper installation can lead to punctures or seam failure

-

Extreme temperatures may affect material performance

-

Mechanical damage during backfilling or operation

-

Long-term aging under UV exposure

For this reason, careful installation, material selection, and regular inspections are essential.

Industry Standards and Regulations

Liner design and installation follow international and national standards. Common references include ASTM testing protocols, Geosynthetic Research Institute guidelines, and environmental regulations for waste containment. Furthermore, compliance ensures safety, durability, and regulatory approval across jurisdictions.

Future Trends and Innovation

Innovation in liner technology continues. Emerging developments include:

-

Smart liners with embedded sensors for real-time monitoring

-

Nanocomposite materials with enhanced strength and permeability control

-

Sustainable liners made from recycled or bio-based polymers

-

Advanced modeling tools for predictive performance analysis

As a result, future liners will improve reliability while reducing environmental impact.

Case Examples and Field Performance

-

Hydropower research shows measurable efficiency gains from lined reservoirs

-

Construction manufacturers report improved safety using textured bubble liners

-

Oil and gas operators achieve successful reservoir stimulation without fracturing

-

Geothermal projects extend well life through corrosion-resistant liners

These examples illustrate how liner technology delivers tangible value across multiple industries.

FAQs

How long do liner systems last?

Service life ranges from 20 to over 50 years, depending on material, exposure, and maintenance.

Are liners environmentally safe?

Properly designed and installed liners significantly reduce contamination risks.

Can liners be repaired?

Yes, most systems allow localized repairs using welding or patching techniques.

Conclusion

From environmental containment to advanced energy applications, liner systems provide essential safety, efficiency, and sustainability benefits. Moreover, liner technology combines material science, engineering design, and quality control to enable reliable operations and regulatory compliance. As innovation continues, these systems will remain foundational to modern infrastructure across industries.

Post Comment